Smart E-Locker

Ecosystem.

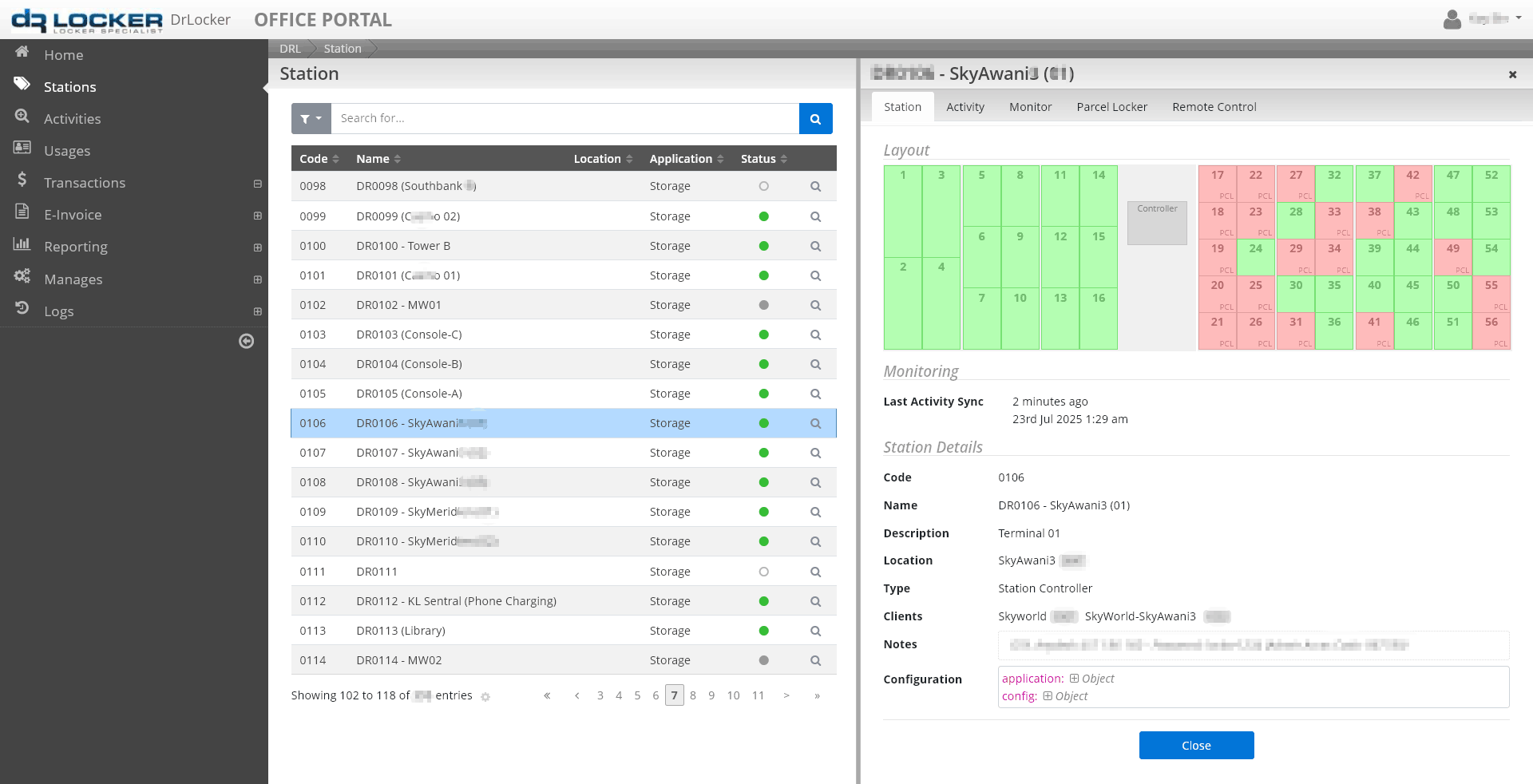

A hardware-software hybrid that automated personal item storage deployed nationwide, providing facility managers with centralized digital control & security in high volume environment.

The "Mess" We Inherited

Our client is evolving their legacy locker business into a networked, smart-locker ecosystem.

By replacing manual handovers with integrated payment terminals and QR-based ticketing, they have enabled a self-service experience that supports credit cards, mobile wallets, and digital authentication for high-traffic environments

15% item loss rate due to manual oversight.

Revenue leakage from unmonitored funds and access.

Zero real-time visibility into locker occupancy.

Legacy hardware lacking remote diagnostic support.

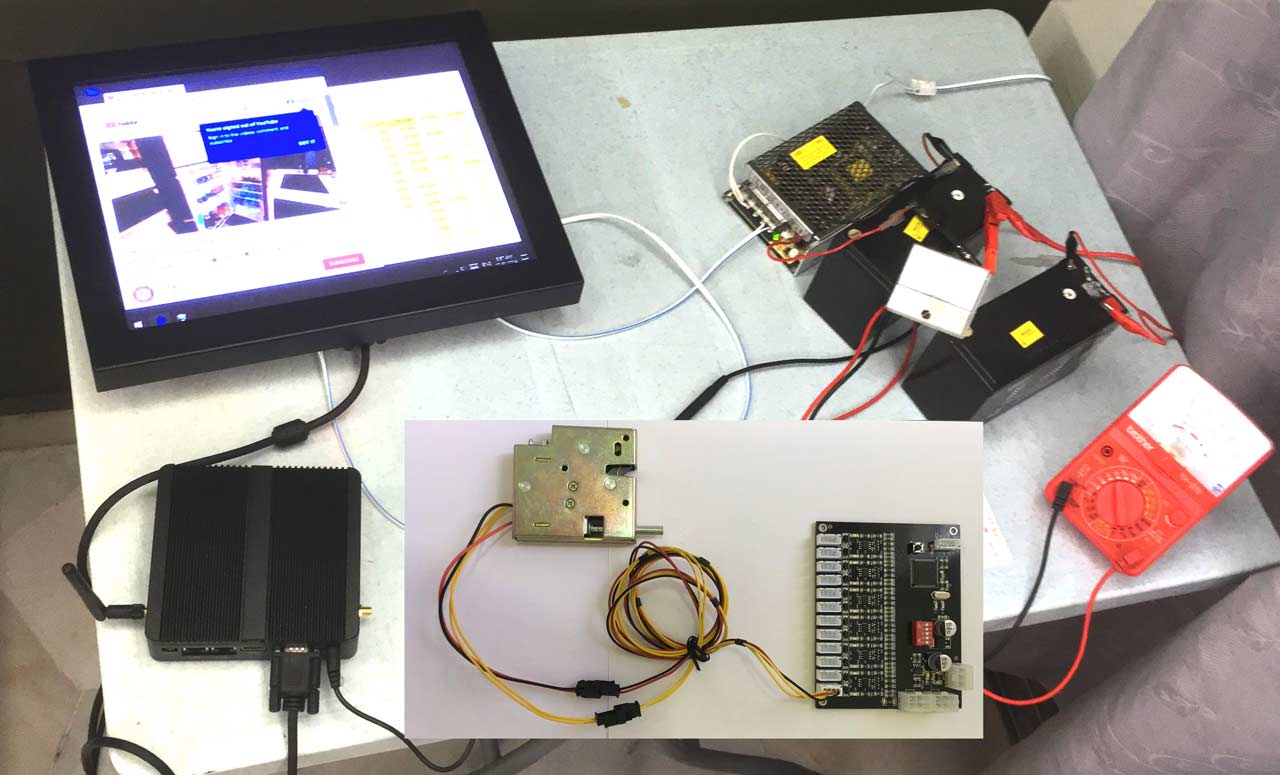

The Cloudby Engineering

We didn’t just build a dashboard. We engineered the entire loop. From custom PCB firmware that controls the locker’s electric strikes to the .Net kiosk UI and the cloud central management hub.

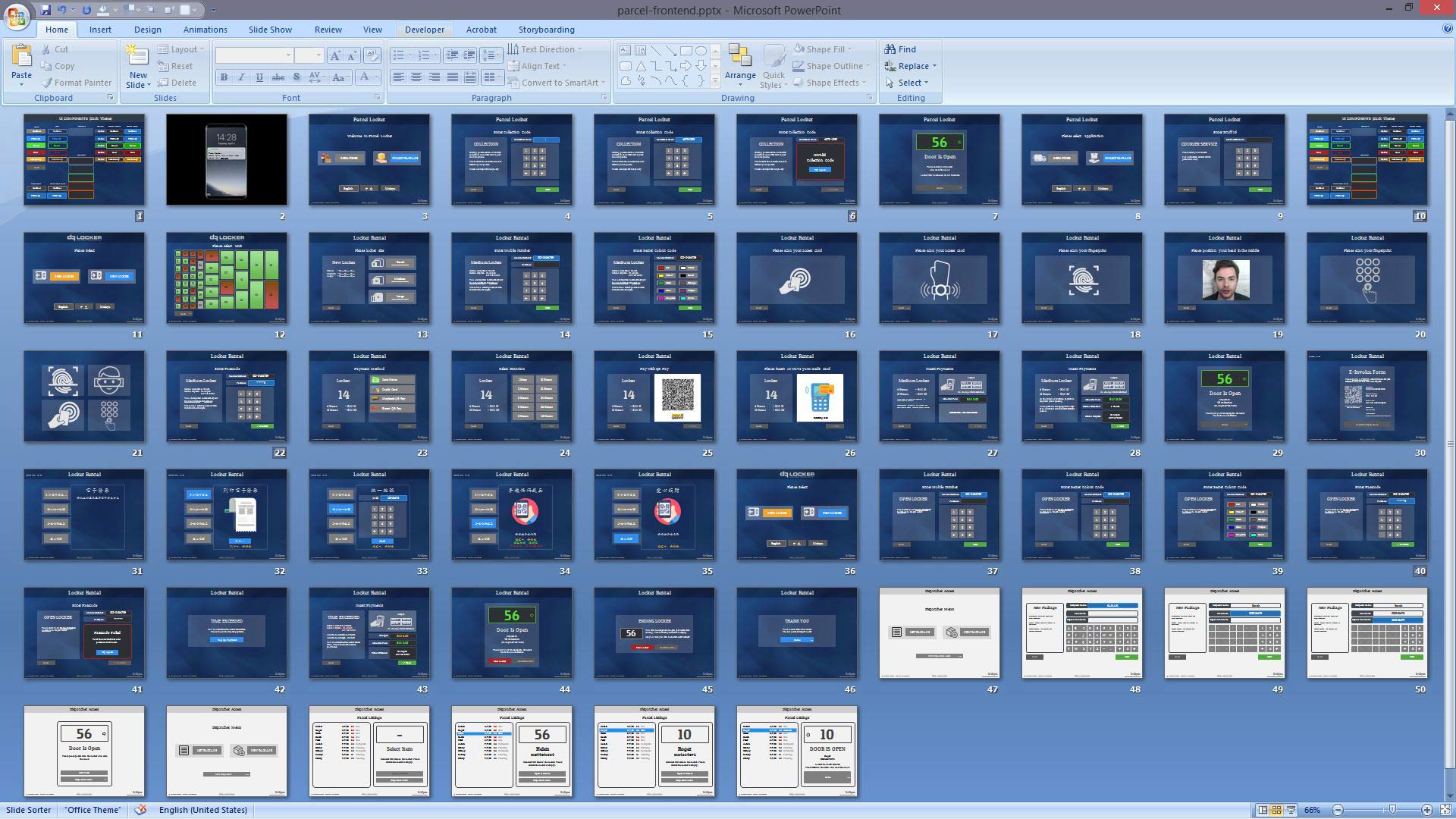

Kiosk UI

Multilingual, interactive, low-latency interface for public users.

Unattended Payment

Realtime EMV terminal integrated handling QR and Credit Cards

Daily Evolution in Action

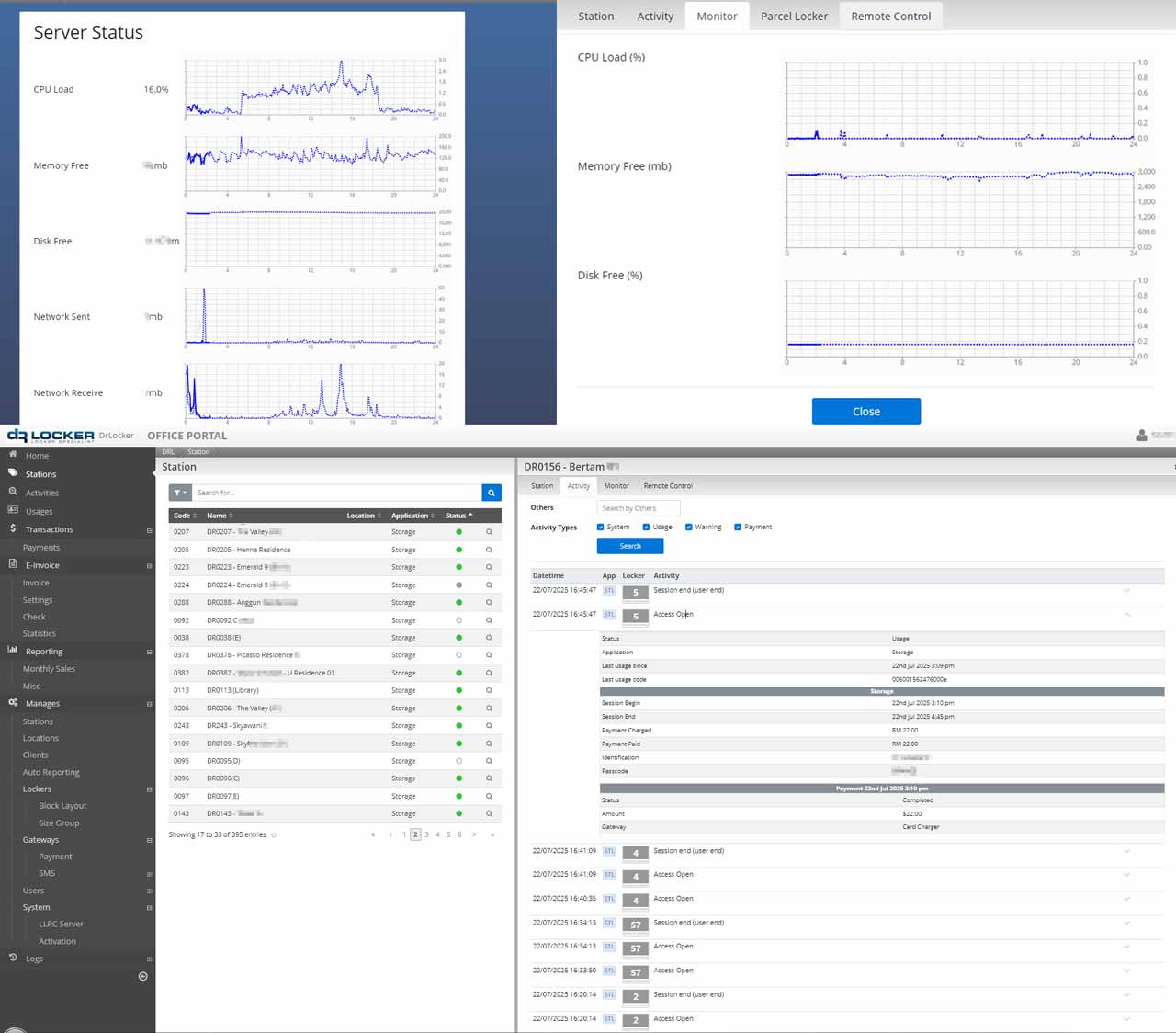

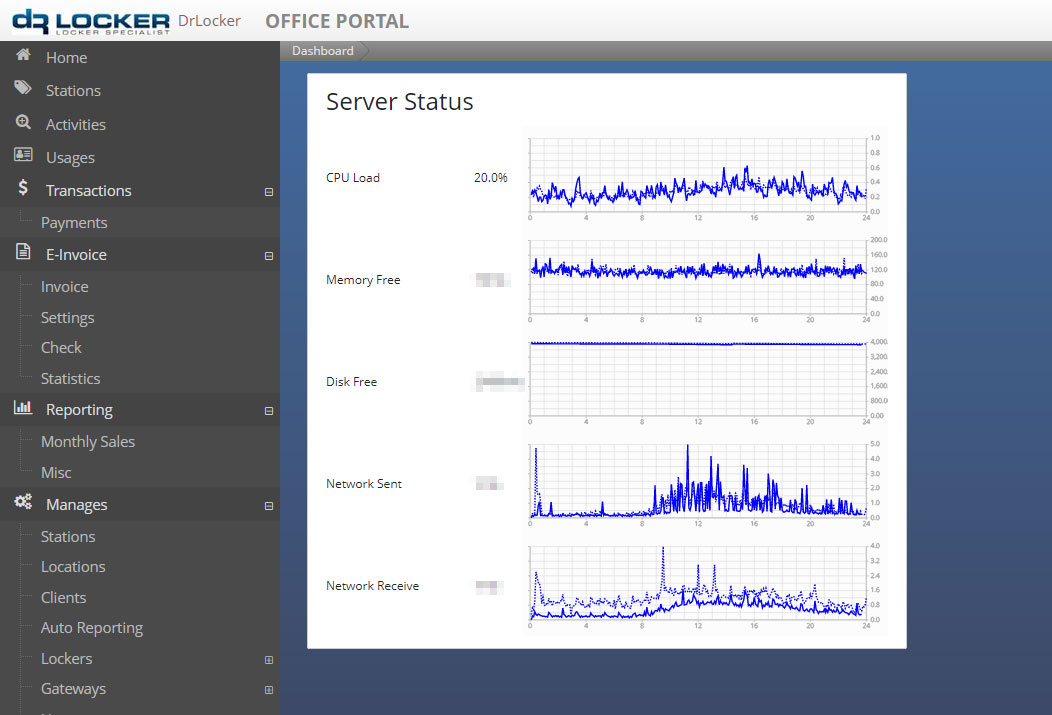

Because this project is business-critical, we don’t just wait for bug reports.

We monitor system health daily and deploy micro-updates to improve locker response times and security protocols.

This is the definition of Active Guidance.

Ready for an Innovation Lab project?

Whether it involves complex hardware or custom cloud logic, we own the entire journey. Let’s discuss your custom build.

Company

About us

Opportunities

Blog

Contact us

Our Experties

Solutions

ERP architecture

White Label & OEM

Showcases

ERP Hosted Services

Self-explore demo

Terms of services