Introduction

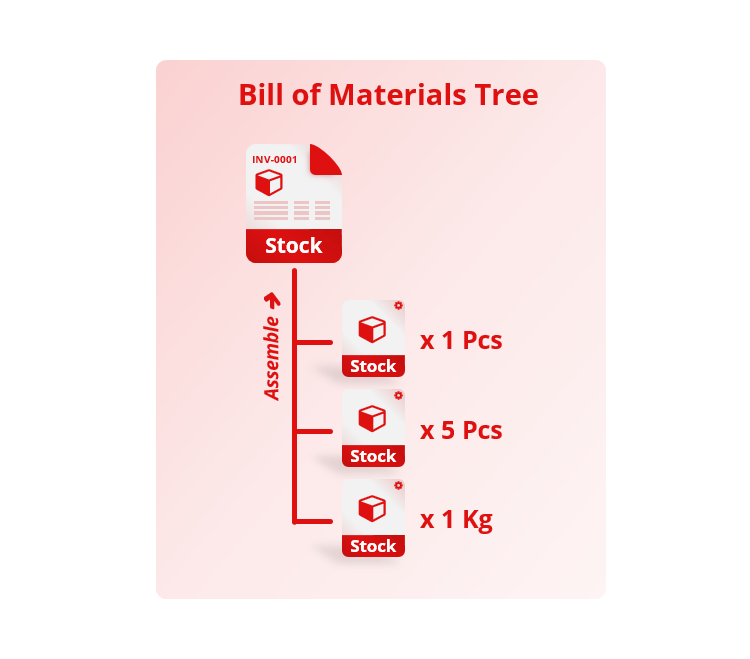

The Bill of Materials (BOM) function allows businesses to track and manage the components and materials needed to produce a final product. It provides a detailed breakdown of the sub-assemblies, parts, and materials required for production and allows for easy tracking of inventory levels and lead times for each component.

The BOM planner also allows for interactive breakdown of sub-components and calculation of lead times based on selected acquisition methods. Additionally, the assembler and disassembler operations in the BOM planner enable easy management of product transformations.

Features

BOM Editor

This feature allows users to create and edit bills of materials for specific inventory items. It includes the ability to specify the components and subassemblies required to produce the end product, as well as any additional information such as quantities and unit of measure.

BOM Planner

The BOM Planner is a tool that helps users to plan and manage the production of inventory items by providing a detailed breakdown of the components and subassemblies required to build a product.

It allows users to calculate the quantities and lead-times for acquiring these components, and can handle multiple products and levels of complexity. This feature can be used to create production schedules, manage inventory and resources, and optimize production efficiency.

Highlights

Enabling Made-to-Order

The BOM function is that it enables businesses to fulfill made-to-order sales. This means that businesses can take a customer’s order for a highly customized product, and use the BOM to quickly and easily determine the components and materials that are needed to build that product.

With this functionality, businesses can better manage their inventory, procurement and production processes, and ensure that they have the necessary components on hand to fulfill the orders in a timely and efficient manner.

Additionally, the BOM planner can help in calculating the lead time to acquire the necessary components and materials.

Alternate Production Process Shortcut

The BOM function, comes with its assembler and disassembler operations, allows small businesses to simply skips the needs for using a production module to manage procurement, allocation, scheduling, and batching process. This greatly simplifies the process according to the business needs.

Learn more

Tours

- Bookkeeping & Automation

- Tips to do thing and that

Tutorials

- Bookkeeping & Automation

- Tips to do thing and that